Rope Access Management System

1st August 2025

Prepared, Reviewed & Approved by

Managing Director Administrator, Nominated IRATA Contact

Rope Access Manager,Technical Authority, Instructor

Table of Contents

-

1. Document Introduction and Requirements

- 1.1 Adherence and Compliance

- 1.2 Application to Management, Planning, and Delivery

- 1.3 Staff Induction and Requirements for New Instructors

- 1.4 Access to Procedural Document

- 1.5 Changes and Revisions

- 1.6 Responsibility for Updates and Compliance

- 1.7 Alerting Staff to Updates

- 1.8 Comments and Suggestions

-

2. Company Organisation and Responsibilities

- 2.1 Insurance Requirements

- 2.2 Sub-Contract Instructors

- 2.3 Overall Health and Safety Responsibility

- 2.4 Rope Access Manager Responsibilities

- 2.5 Minimum Qualification for Rope Access Manager

- 2.6 Skills Requirements for Rope Access Manager

- 2.7 Ensuring Instructor Competence

- 2.8 Management Skills Training

- 2.9 Communication and Control Systems

- 2.10 Duty to Ensure Competence and Supervision

- 2.11 Administrative Responsibilities

- 2.12 Incident Reporting

- 2.13 Safety Notices

- 2.14 Annual Internal Audit and Meetings

- 2.15 Review and Updates

- 2.16 Health and Safety Meetings

- 2.17 General Responsibilities Instructor (includes Job Description, Health and Safety Responsibilities and Duties, Whilst at Work, Induction Training, Summary, Management of Employees, BeSafety Health & Safety Rules)

- 2.18 Instructor Experience and Competence

- 2.19 Level 3i as Instructors

- 2.20 Skills for Level 3i Instructors

- 2.21 Ensuring Supervisory Skills

- 2.22 Familiarity with Environment

- 2.23 Personnel Requirements

- 2.24 Candidate Feedback (repeated, includes Administration, Management, and Planning)

- 2.26 Administration Person

- 2.27 Role of Training Administrator

-

3. Instructor Requirements & Competence

- 3.1 Competence Requirements

- 3.2 Training and Allocation

- 3.3 Physical Fitness

- 3.4 Pre-Use Inspection and Responsibilities

- 3.5 Hazard Understanding and Induction

- 3.6 Defect Detection

- 3.7 References and Skills Test

- 3.8 Attitude and Aptitude

- 3.9 Qualification

- 3.10 Policy on Aptitude, Training, and Experience

- 3.11 Log Books and Certification

- 3.12 Supervision of New Instructors

- 3.13 Refresher Programme

- 3.14 Selection Based on Experience

- 3.15 Competence and Training Needs

- 3.16 Records

- 3.17 Additional Precautions for New Instructors

- 3.18 IRATA Qualification (Level 3i)

- 3.19 Certification Validity

- 3.20 Refresher Training

- 3.21 Logbooks

- 3.22 Personnel Files

- 3.23 Staff Induction

- 3.24 Medical Certification

- 3.25 Insurance and First Aid

- 3.26 Disciplinary Procedures

-

4. Training Methods & IRATA Training Delivery

- 4.1 Course Content and Delivery

- 4.2 Training Manual and Lesson Plan

- 4.3 IRATA Levels and Flowchart (includes Level 1, Level 2, Level 3 descriptions, content, who will benefit, structure)

- 4.4 Independent Assessment

- 4.5 Assessor Insurance

- 4.6 Debrief

- 4.7 Pass Procedures

- 4.8 Trainee Signature

- 4.9 Trainer Signature

- 4.10 Fail Procedures

- 4.11 Removal from Course

- 4.12 Planning and Management Objectives

- 4.13 Risk Assessment

- 4.14 Risk Assessment Details

- 4.15 IRATA Form 006

- 4.16 Eliminating Hazards

- 4.17 Emergency Scenarios

- 4.18 Documents at Venue

- 4.19 Sign-In and Induction

- 4.20 Toolbox Talk

- 4.21 Pre-Use Checks

- 4.22 Buddy Checking

- 4.23 Pre-Use Checks on Equipment

- 4.24 Additional Checks

- 4.25 Anchor Lines Rigging

- 4.26 Monitoring

- 4.27 Pendulum Situations

- 4.28 Access Restrictions

- 4.29 Protecting Anchors

- 4.30 Communications

- 4.31 Anchor Points

- 4.32 Two-Rope System

- 4.33 Attachment Principles

- 4.34 Anchor Types

- 4.35 System Strength

- 4.36 Anchor System Components

- 4.37 Rigging Angles

- 4.38 Deviations

- 4.39 Horizontal Tensioned Lines

- 4.40 Checking Anchor Lines

- 4.41 Avoiding Damage

- 4.42 Anchor Reliability

- 4.43 Anchor Lines

- 4.44 Independent Systems

- 4.45 Primary and Back-Up Devices

- 4.46 Double Protection

- 4.47 Intended Purpose

- 4.48 Y Hang System

- 4.49 Rigging Angles

- 4.50 Independent Attachments

- 4.51 Rope on Ground

- 4.52 Suitable Anchors

- 4.53 Positioning

- 4.54 Linking Anchors

- 4.55 Configuration

- 4.56 Length Check

- 4.57 Slack Avoidance

- 4.58 Connections to Safety Lines

- 4.59 Mid-Height Attachments

- 4.60 Long Anchor Lines

- 4.61 Tensioned Lines

- 4.62 Doubled Anchors

- 4.63 Working with Tensioned Lines

- 4.64 Aid-Climbing

- 4.65 Work Seats

- 4.66 Confirmation to Proceed

- 4.67 Descent

- 4.68 Deviation Anchors

- 4.69 Protection in Rope Access Area

- 4.70 Entering Hazard Zone

- 4.71 Hazardous Areas

- 4.72 Approaching Edges

- 4.73 Barriers

- 4.74 Anchor Line Vulnerabilities

- 4.75 RAP Hierarchy

- 4.76 Anchor Line Protectors

- 4.77 Abrasive Surfaces

- 4.78 Mid-Anchor Situations

- 4.79 Maintaining Position

- 4.80 Types of Protectors

- 4.81 ICOP Annex P

- 4.82 Exclusion Zone

- 4.83 Controlling Access

- 4.84 Tools and Lanyards

- 4.85 Unattended Areas

- 4.86 Work Support Seats

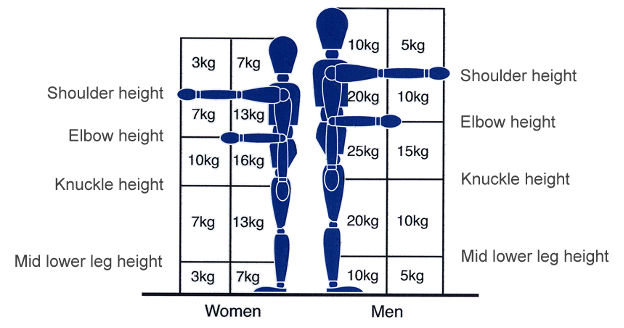

- 4.87 Manual Handling Regulations

- 4.88 Mechanical Loads

-

5. Equipment

- 5.0 Safe Working Loads

- 5.1 Conformity to Standards

- 5.2 Selection and Purchase

- 5.3 Certificates and Traceability

- 5.4 Marking

- 5.5 Harness Assembly

- 5.6 Equipment Set-Up

- 5.7 Connectors

- 5.8 Cowstails

- 5.9 Fall Arrest Lanyards

- 5.10 Fall Arrest Blocks

- 5.11 Descenders

- 5.12 Ascenders

- 5.13 Back-Up Devices

- 5.14 Rope Types

- 5.15 Rope Inspection

- 5.16 Helmets

- 5.17 Ground Level Helmets

- 5.18 Master Equipment Register

- 5.19 Assessment Before Use

- 5.20 Intended Purpose

- 5.21 Fail to Safe

- 5.22 Product Information

- 5.23 Thorough Examination

- 5.24 Inspection Intervals

- 5.25 Unserviceable Equipment

- 5.26 Repair

- 5.27 Storage

- 5.28 Hanging and Racking

- 5.29 Procurement

- 5.30 Selection

- 5.31 Traceability

- 5.32 Marking

- 5.33 Inspection Types

- 5.34 Pre-Use Check

- 5.35 Formal Inspection

- 5.36 6-Monthly Inspections

- 5.37 Manufacturer Guidance

- 5.38 Quarantine

- 5.39 Interim Inspections

- 5.40 Doubtful Equipment

- 5.41 Records

- 5.42 After Use

- 5.43 PPE Use

- 5.44 Permitted Equipment List (includes Full Body Harness, Chest Harness, Maillon Rapides, Connectors, Descenders, Ascenders, Safety Back Up Devices, Energy Absorbing Lanyards, Helmet, Low Stretch Rope, Dynamic Rope, Cow’s Tails, Wire Strops, Webbing Slings, Work Seats, Rope Protection Devices)

-

6. Communication

- 6 Efficient System

- 6.1 Accidents

- 6.2 Rescue Arrangements

- 6.3 Rescue Plan (includes Foreword, Plan 1, Plan 2, Plan 3)

- 6.4 Administer First Aid

- 6.5 Self-Rescue

- 6.6 Prompt Help

- 6.7 Rescue Equipment

- 6.8 Emergency Instructions

- 6.9 Rescue & Emergency Procedures

- 6.10 Suspension Syncope and Medical First Aid

- 7. Accidents & Incidents

- 8. Candidate Welfare & Training Venue

1 Document Introduction and Requirements

Document title BS.01 is the procedural document to be followed for the execution of all IRATA Rope Access Training courses to the IRATA TACS document by BeSafety Ltd. BeSafety is an IRATA Rope Access training provider. This document BE.01 details the procedures and quality controls in place to ensure the safe, efficient, and compliant delivery of IRATA rope access training by BeSafety Ltd and its Instructors.

1.1 All staff participating in BeSafety IRATA rope access training will be required to adhere and comply to this document BE.01 and the following procedures contained within.

1.2 The procedures contained within this document will apply to the management and planning and physical delivery of IRATA Rope Access Training conducted by BeSafety staff and instructors. All BeSafety Staff will sign BeSafety form 001 Receipt Form, to verify that they have received, read and understood the content of this procedure document titled BE.01 and its associated forms and appendix documents and supporting training manual. This will then be kept on file in their personal records.

1.3 All staff employed in relation to IRATA Rope Access Training be it Management or physical delivery will receive an induction of this procedure document, by the Managing Director and sign form 001, All BeSafety personnel plus any engaged sub-contractors participating in IRATA Rope Access Training are required to comply with this procedure document. In addition any new Instructor employed by BeSafety will be provided with an Induction of the training venue and the following documents:

- BE.01

- Site Risk Assessment

- Company Training Manual

- Form 006

- BeSafety company relevant Forms

- BeSafety Appendix documents

1.4 All staff will have unlimited access to this Procedural document titled BE.01, The latest copy will always be available on request, held in the office and issued electronically on request. Staff should always check that they have the most up to date version of this document by referring to the Procedure document control Page attached to the front and checking that it is the latest and most up to date version.

1.5 When changes to this procedure occur it will be identified on the Procedure document control page attached to the front of this document and on form 012 Procedures revision form.

1.6 The Managing Director and The Rope Access Manager will be responsible to ensure that this procedure document is up to date and relevant to all and any changes to current UK Rope Access legislation, issued standards and including IRATA ICOP and supporting annex’s, IRATA TACS document, IRATA’s Memorandum & Articles and Bye Laws. Plus all UK and European government publications within the legislative framework of the rope access industry. The Rope Access Manager will monitor communications from IRATA including issued Safety notices/bulletins and amend this procedure document accordingly. Andrew Roffe is responsible for all procedural and regulatory matters relating to IRATA Rope Access Training, including compliance with IRATA ICOP, IRATA TACS Document. The Rope Access Manager will be the Technical Authority and Management Contact for IRATA Training membership. He will be responsible for IRATA membership and its annual fees.

1.7 The Rope Access Manager, will have the responsibility to alert all staff of the updates to this document, which will be done in writing as required on form 012. Staff will be requested to sign the document receipt form 01 to verify they have been informed and understood these procedures. This 01 form will be held within the staffs employment file.

1.8 All comments and suggestions on the content or implementation of this procedure document are encouraged from ALL staff in their induction and should be addressed and communicated to the Rope Access Manager in writing.

2 Company Organisation and Responsibilities

2.1The company shall hold suitable and appropriate employers and public liability insurance. Where appropriate, product liability and professional indemnity cover shall also be provided. A copy of the company’s current public and employer’s liability insurances detailing the use of industrial rope access methods shall be held at the training venue.

2.2In the unlikely occurrence that IRATA qualified sub-contract Instructors are utilised at BeSafety Ltd, they shall provide their own public liability insurance, suitable checks shall be made to ensure that the cover is adequate and current, and of their current IRATA Instructor Status. They will be required to receive an induction in these procedures and its forms, the Training Venue Risk Assessment and all related BeSafety IRATA Training documents and controls, they too will be requested to sign form 001.

2.3The Managing Director/Rope Access Manager will have overall responsibility for all health and safety matters relating to IRATA Rope Access employees plus third-party persons in relation to BeSafety IRATA rope access Training activities. They will also enforce company policies by ensuring staff regular attend at management meetings, and to ensure meetings are held to discuss and review policies, procedures and documents. The Managing Director has ultimate responsibility for all health and safety matters relating to employees, trainees, public and any others engaged in BeSafety Ltd IRATA rope access training activities. This also includes the annual declaration

2.4Andrew Roffe - BeSafety Rope Access Manager will have the responsibility to ensure full technical compliance to the requirements of IRATA Training membership and ensure the safe delivery of IRATA Rope Access Training as per these procedures and the IRATA ICOP and IRATA TACS Document. He will be responsible for the Training manual and its review; The Rope Access Manager will have the technical expertise and experience to effectively manage all IRATA Rope Access Training related tasks. BeSafety Rope Access Manager will be the identified IRATA Technical Authority. If at any time the current Rope Access manager should leave employment with BeSafety Ltd then the Managing Director will advise IRATA and seek immediate replacement of this person and position with them being as equally technically qualified.

2.5The minimum qualification of the BeSafety Rope Access Manager will be IRATA level 3i. The Rope access manager is responsible for planning, implementing and reviewing the IRATA Training delivery and of a safe system of work

2.6The Rope access manager should meet the requirements of and have the following skills:

- Competence and experience of the work being managed

- The ability to communicate requirements to rope access instructors

- The ability to create, implement and review training methods and techniques, and be able to assess which methods are appropriate for each training task;

- The ability to ensure correct operation of the rope access training management system.

2.7The Rope access manager has a duty to ensure that IRATA rope access Training Instructors and Trainee IRATA Instructors are competent for the training task in hand.

2.8The Managing Director should ensure that the rope access manager has the necessary management skills for this role and some form of training in management. He/She will be responsible for IRATA Instructors at BeSafety Ltd

2.9The Rope Access Manager will communicate requirements to IRATA rope access Instructors. He will create, implement and review control systems, and be able to assess which control measures are appropriate for Training.

2.10The Rope access manager will have the duty to ensure that IRATA rope access Instructors are competent for the task in hand. He will supervise and manage instructors and provide updates of techniques, training methods, the review of the training manual and be responsible for the mentoring and the supervision and management of instructors. The Rope Access Manager has the duty to ensure Instructors are competent. (Please see Skills and Competency section).

2.11 The Rope Access Manager will be responsible as the administrative contact for IRATA membership for BeSafety Ltd. He will be responsible for all communication directly with IRATA, including the following: He will be responsible for completing IRATA form 006, The Review of these IRATA Rope Access Training Procedures, The BeSafety IRATA Training Manual, Training Course Content and Lesson Plans, Training Venue Risk Assessment, IRATA Rope Access Training Site Rescue Plans, The Selection of IRATA Rope Access Training Equipment and associated materials and ensuring its competent examination and inspection recorded on the equipment inspection inventry. He will also be responsible for all training venue structures and anchorages.

2.12 The Rope Access Manager would be responsible for the immediate completion of IRATA incident reporting portal in the event of an accident, incident, or dangerous occurrence. The Rope Access Manager would be responsible for recording, investigating, and reporting to the relevant authorities in line with the requirements of UK law. All incidents will be recorded on the company accident and incident report Form 002.

2.13The Rope Access Manager will display all necessary safety notices including IRATA safety notices and bulletin in the training venue.

2.14The Rope Access Manager will be responsible for completing the annual internal audit as per the IRATA audit 059 internal audit checklist. Any non conformance found on Internal Audit will be recorded on form 013 Internal Audit Non-Conformance Form and the resulting corrective action required recorded and actioned by the Rope Access Manager. He will also attend a minimum of one IRATA General Meeting or relevant committee meeting within the membership year, so that they are fully conversant with the activities, workings and requirements of the Association.

2.15The Rope Access Manager with the help and Support of the Managing Director will be responsible for the review and necessary updates to this titled procedural document, Including ensuring that all staff are made aware of changes and updates and a record of this kept by ensuring each member of staff signs a document revision form 01. This form will be held on the employee file.

2.16The Rope Access Manager will encourage open, operational review and feedback by arranging Regular IRATA Rope Access Training Health and Safety meetings concerning health and safety, held both formally and informally. It is important to involve all staff and to encourage everybody to attend and to contribute to all matters that may affect safety. These will generally be carried out on a quarterly basis informally, however if an important matter arises, meetings can be called at any time and reviews of the procedures can be carried out at any time. The meetings headed and chaired by the Rope Access Manager to enable any operational IRATA Rope Access Training Instructor staff to discuss and formally record their views, opinions, feedback and findings, and distributing his findings to all staff. Rope Access Training can only be carried out in a reliable safe manner where training staff are deemed competent to train and experienced in the delivery of training.

2.17General Responsibilities Instructor

Instructor Job Description:

Level 3i – IRATA Rope Access Instructor

The Instructor is responsible for the Health and safety of himself, the candidates engaged on the training course, and any visitors to the training venue. Also, all rope access related activities at the rope access training centre. He may work on the ropes as part of the training delivery, providing he has made suitable arrangements for all aspects of the safety of himself and the candidates while so occupied. These arrangements will include a pre-arranged rescue system and fully briefed candidates. The level 3i Instructor is also responsible for the formal reporting of incidents, accidents, unsafe conditions and unsafe acts that might occur to the Rope Access manager and they can do this by using form 011. There will always be an Instructor on site, providing constant supervision during rope access training. Rope access Instructors engaged by BeSafety Ltd in the delivery of Rope Access Training are responsible for executing the designated activities for which they are qualified and competent. This is to be done in a safe and professional manner, adhering to the requirements of these Training procedures. All personnel have a responsibility to report incidents, accidents, unsafe conditions and unsafe acts to the Rope Access Manager. . IRATA Rope Access Training can only be carried out in a reliable safe manner where staff are deemed competent and experienced. They are subject to appropriate levels of supervision at all times by the Rope Access Manager

Health And Safety Responsibilities And Duties Of Employed Instructors

Instructors have paramount responsibility for the health and safety of the candidates within the area of their control. They can greatly influence company / candidate relationships by helping to achieve company health and safety policies. They may call on the help of the Rope Access Manager Who has the responsibility for providing health and safety assistance including other specialists to help them in exercising their responsibilities.

They will:

- Ensure that the Company health and safety policy statement and Company Training procedures are fully implemented;

- Promote a high standard of health and safety and Training;

- Ensure that suitable and sufficient Rope s are conducted, reasonable steps are taken to minimise all risks found, and that the assessments are reviewed regularly;

- Help Establish written safe training procedures and instructions, for use within their work area;

- Ensure that all candidates under their control are fully conversant with, and understand, the Company health and safety rules as it applies to them;

- Ensure that adequate training is given to candidates within their remit to ensure compliance with our company health and safety standards and IRATA’s Code of Practice;

- Ensure that no candidate is required to undertake any task without adequate training / instruction or which exceeds their capability;

- Ensure that recommendations which will eliminate or reduce hazards or prevent recurrence of accidents are implemented as soon as possible;

- Ensure that health and safety aspects for new or revised training techniques within their areas of control are fully considered;

- Establish regular health and safety inspections of all areas within their control;

- Ensure that health and safety problems / queries referred to them are resolved;

- Be conversant with the accident reporting procedure. Investigate all accidents and dangerous occurrences as soon as possible, taking or recommending action to prevent a recurrence, in conjunction with the company appointed competent person;

- Notify The Rope Access Manager immediately of any serious accident or dangerous occurrence

Whilst at work all employed Instructor staff must:

- Use any equipment or safety device provided to them by the company in accordance with both training and any instructions they have received in the use of the equipment;

- Inform The Rope Access Manager or any other employee with specific responsibility for Health and Safety of:

- Any work situation which might present a serious and imminent danger;

- Any shortcomings in the Health and Safety arrangements, even when no immediate danger exists;

- So that BeSafety Ltd can take remedial action if needed.

- Co-operate with BeSafety Ltd to enable compliance with their statutory duties for Health and Safety under law and IRATA’s code of practice and TACS Document.

They must Take reasonable care for their own Health and Safety and that of others who may be affected by their actions or omissions whilst at work.

In order to secure the Health and Safety of all employees, BeSafety Ltd will provide Health and Safety training to all new employees, which will be incorporated into general induction training. Induction training will commence prior to the delivery of any training by the employee so that employees are familiar with basic training procedures.

The Rope Access Manager is responsible for conducting this training and retaining any records. The training will last as long as required and The Health and Safety component of induction training will contain the following:

- Company Health and Safety Policy – the contents of our company policy statement will be covered, including the responsibilities set out in the policy, and will enable the employee to become acquainted with the organisational requirements

- BeSafety Ltd’s IRATA Training Procedures, training manual and Risk Assessment.

- Accident reporting / first aid procedures – this will cover the action to be taken when an accident has occurred, the person to be informed and where to go for first aid (this section will also cover our company’s procedure as to the investigation of accidents; the reporting procedure will be explained so that the employee is aware of what will happen when an accident occurs);

- Fire precautions and procedures, including BeSafety site RESCUE emergency plans;

- Introduction to safety legislation – the employee will be introduced to the legislation that applies to our company and the workplace;

Examples of legislation that will be covered include:

- Health and Safety at Work, etc Act 1974 (essential);

- Management of Health and Safety at Work Regulations 1999 (as amended) (essential);

- Personal Protective Equipment at Work Regulations 1992 (where appropriate);

- Manual Handling Operations Regulations 1992 (where appropriate);

- Work At Height Regs 2005

- Provision and Use of Work Equipment Regulations 1998 (where appropriate);

- IRATA ICOP and TACS

- Safety rules and BeSafety LTD Training procedures – this section will cover the company and departmental safety rules, procedures and any safe systems of work in the delivery of Training

After a suitable period of time, the training will be followed up to assess the effectiveness and to correct any deficiencies or misunderstandings. The induction will form the basis of any ongoing training in the future.

A record will be kept of each employee who has received this training, and they should be asked to sign a statement indicating they have read and understood the Training Procedures. This record should also be dated.

Summary

Effective induction training is essential in order to instil our company safety culture and high standards of training delivery. As soon as an employee commences their employment with BeSafety Ltd the following procedure will be followed:

Effective induction training is essential in order to instil our company safety culture and high standards of training delivery. As soon as an employee commences their employment with BeSafety Ltd the following procedure will be followed:

- Arrange for induction training to be given prior to the first day of employment;

- Relevant information will be provided to the employee in respect of risks to his / her Health and Safety and on preventative and protective measures to candidates

- Information will be provided on the Company's emergency arrangements

- Ensure that the employee understands all the information provided to them and that they have the opportunity to ask any questions in relation to the staff training; after a suitable length of time the training should be followed up with the employee to assess its effectiveness and to correct any misunderstandings.

Management of Employees

- Section 2 of the Health and Safety at Work Act 1974 imposes a general duty on employers to provide as much information, instruction, training and supervision to ensure the Health and Safety at Work of the employees

- Training is therefore an essential duty of BeSafety Ltd. To this end, it is the policy of the company to train all staff in all aspects of health and safety in order that they should impart these rules to all new candidates.

- It is the responsibility of all staff to ensure that all candidates are adequately trained, and adhere to all the safety rules formulated by the company.

BeSafety Health & Safety Rules

Instructors

- These rules are to be used as the general Health & Safety rules issued by the company for employed Instructors.

- Instructors must have seen and understood the company’s Health & Safety policy.

- They must ensure, as far as reasonably possible, that all employees and candidates within their jurisdiction also know and understand the Health and Safety rules.

- Candidates must not be allowed to undertake any work at height training that puts Health & Safety of themselves or others at risk. It is the responsibility of YOU the Employed Instructor to have a legal duty of care for the candidates.

- Make sure that candidates are fully trained and familiar with the equipment they operate, and that it is used properly.

- Where protective safety equipment is provided to candidates, make sure that it is used for the purpose of which it is designed.

- Where defective or suspect equipment is found, make sure it is taken out of service, labelled as such placed in quarantine and examined as soon as possible.

- Make sure that candidates are familiar with the buildings in which they are being trained, particularly fire precautions, emergency and rescue procedures and the fire exits.

- Employed trainers are to have first aid certs and know the location of site First aid.

- Ensure that first aid kits are available, and where necessary utilised.

- Report all accidents (however trivial) without delay and ensure entry is made in the accident book.

- Set a good example to all candidates and encourage an active interest in IRATA, Health & Safety and Industry best practice whilst at the training venue and working on behalf of BeSafety Ltd.

BeSafety Instructors role is to ensure that IRATA Rope Access Training proceeds in accordance with these procedures, the requirements of IRATA Training Membership and the IRATA ICOP and TACS Document and any European and UK Legislation relating to IRATA Rope Access Training.

The Instructors role is to ensure that IRATA Training proceeds in accordance with these procedure’s, in the manner set out in the documentation and with the aim of zero accidents.

2.18It is essential that Instructors have the experience and competence to supervise the rope access work and any potential rescue for each rope access training event under their supervision.

2.19Within BeSafety Trained and certified Level 3i rope access technicians are permitted to be Rope Access Instructors. The Rope Access Manager will ensure that IRATA Level 3i have the necessary supervisory skills before they are given such a role, as rope access technical skills alone are no assurance that a Level 3i is competent to supervise. Some form of training in supervision is recommended.

2.20Level 3i IRATA rope access Instructors will require the following skills:

- The experience and competence to supervise the rope access training and any potential rescue for each rope access project under their supervision

- The ability to communicate to IRATA rope access candidates the IRATA rope access safety requirements and to manage day-to-day problems at the training site

- Leadership abilities appropriate to the training delivery

- The ability to monitor closely both training and candidates for rope access safety and to be able to identify any shortfalls in the required competence of candidates

- A thorough knowledge of hazard identification and risk assessment, and methods of training site management

- The ability to understand and implement the content of safety Risk Assessments

- The ability to complete and maintain relevant documentation

- The authority to make decisions to ensure the safety of IRATA rope access candidates, the public and the rope access training venue worksite

2.21The Rope Access manager will ensure that employed IRATA Level 3i Instructors have the necessary supervisory skills before they are given such a role by conducting interviews prior to engagement. The Rope Access Manager will ensure Instructors are updated on techniques and changes to training methods and the training manual.

2.22BeSafety Instructors should be familiar with their work environment, the working conditions and practices, and, in particular, the essential liaison necessary with candidates. By use of the Reporting form 011 there is a clearly defined reporting system to the rope access manager.

2.23All personnel involved in IRATA training for BeSafety Ltd will be IRATA Level 3i minimum. All staff used will receive BeSafety Ltd Training Procedures and training manual Staff Responsibilities, BeSafety Risk Assessment and General Rules and a practical induction including on going staff training and mentoring by the rope access manager. On larger courses consideration may be given to the use of an IRATA Level 3i sub contractor as an assistant instructor, however the course will remain at all times under the direct supervision of the full time employed BeSafety Level 3i.

2.24The Managing Director will ensure candidate customer Instructor satisfaction feedback is collated using a variety of methods of communication including feedback sheets at end of courses appendix document 010 IRATA Training Course Administration, Management and Planning.

2.24BeSafety IRATA Rope Access Training and its courses will require Planning, Administration, Organisation and Financial Management, including the commitment to meet the requirements of IRATA Training membership and the IRATA TACS Document.

2.26Where required BeSafety will utilise an Administration Person to assist the Managing Director, The Rope Access Manager and The Instructor. This nominated person is currently known as Training Administrator. If the Training Administrator is unsure of any technical query, they will consult with the Rope Access Manager who will either deal with situation themselves or feed the correct information back to the training administrator.

2.27The Role of the Training Administrator is a nontechnical role that includes all course admin and does not require practical Rope Access skills, but an understanding of the IRATA Training course requirements.

The Roles and responsibilities of the Training Administrator is as follows:

- To Advertise IRATA Rope Access Training courses including dates, times and location on the IRATA Website

- To Maintain and Advertise IRATA Rope Access Training on the BeSafety Company Website

- To Administer the booking of all courses by all candidates including financials i.e. Invoicing and accounts payable including fees due to IRATA

- To maintain the appropriate level of candidates per course for the Instructor i.e. a maximum of 6 candidates at any level for 3i qualified Instructor

- To book and organise an IRATA ASSESSOR for each IRATA Training Course with the maximum 8 candidates :1 Assessor ratio

- To respond to all candidate course enquiries via website, email or telephone and send out relevant course information or facilitate candidates to include:

- Booking Form with Price and Course Dates

- Self Cert Medical Form (See Below)

- Joining Instructions

- IRATA Scheme Flowchart

- A copy of the relevant syllabus sent to all new IRATA course applicants in advance.

- All applicants are advised in advance of how the IRATA system is structured and how they may progress through it.

- Applicants are advised in advance of the advantage of a relevant trade background when it comes to subsequently finding employment with their IRATA certificate.

- All applicants are advised in advance of the physical and mental demands of rope access training.

- Prior to commencement of training all trainees are required to have current medical certification. As a minimum this will involve the trainee self-certifying that they have no contraindications for this type of training using the IRATA form: “Statement of Medical Condition”. This form is supplied to trainees in advance.

- At commencement of the course copies of the IRATA ICOP and TACS document will be supplied by email to all candidates.

- To ensure A copy of the BeSafety Ltd training manual will be supplied to all trainees on arrival at the course.

- To facilitate the Travel and Accommodation enquiries of candidates and visiting Assessors

- To ensure all course paperwork including the IRATA Registration to Tech Connect, IRATA Theory Question Papers and Level 3 forms plus the candidate is onboarded to TechConnect to enable the assessor to access the ADF via the IOS system prior to the assessment

- To file online registrations to the IOS system

- To maintain all Personnel files of BeSafety Staff

- Maintain Candidate Welfare facilities and First Aid Kit

- To Ensure Courses will ONLY be run with a maximum recommended Trainee to IRATA 3i Instructor ratio of 6:1, and on larger courses to a maximum of 8 candidates, a second IRATA 3i qualified Instructor will be used. The second instructor may be an experienced Level 3i.The principal full-time trainer retains absolute overall responsibility for the safety and organisation of the course.

- To maintain and administer Staff Certification

- To liaise with IRATA Administration team relating to candidate or course queries

- Maintenance of all END of Course IRATA Training course paperwork:

- Candidate Question Papers

- Medical Statements

- The Registration process

- ADF for completion on IOS system

- Copies of Assessment Form

- Level 3 forms

- Course Feedback forms

3 Instructor Requirements & Compentence

3.1Besafety IRATA Training must only be carried out in a reliably safe manner where people are competent. To be considered competent, a rope access instructor needs to have sufficient professional or technical training, knowledge, and actual experience to carry out their assigned duties at the level of responsibility allocated to them.

They must:

- Understand the limitations of their level of training with regard to work practices

- Understand the various uses of the equipment they use and its limitations

- Select equipment correctly

- Use the equipment properly

- Inspect the equipment they use

- Maintain and store the equipment they use

3.2Besafety Instructors must be trained and competent to carry out any training task that they are to undertake, including candidate rescue/retrieval and should only be allocated training tasks appropriate to their level of training and only after mentoring has occurred by the Rope Access Manager.

3.3Be sufficiently physically fit and free from any disability that might prevent them from working safely at height and have signed IRATA form 014R and held on their personnel file, candidates will also sign this form and again be kept for a minimum of 3 years.

3.4Instructors must be competent in the pre-use inspection of theirs and the candidates PPE equipment, including an understanding of when equipment should be withdrawn from service or placed in quarantine. The Maintenance of the Training venue and its structures including ensuring the control measures are enforced of the training venue risk assessment. Instructors will be responsible for the organization and daily running of an IRATA training course including:

- Candidate Inductions

- IRATA Assessor Inductions

- Storage of Equipment used in Training

- Paperwork relevant to the course

- Candidates Welfare

3.5They will understand potential hazards related to their work under consideration and be able to carry out appropriate training candidate site safety inductions including health and safety rules, welfare, first aid and training site emergency and rescue plan procedures. Instructors will ensure candidates receive induction at the beginning of all courses and sign form 009.

3.6Instructors will have the skills to detect technical defects or omissions in their work equipment, recognize implications for health and safety caused by such defects, and be able to specify a remedial action to mitigate those implications. (Please see quarantine action) Instructors will be responsible for the supervision and safety of candidates at all times. They will deliver candidate training for both practical and theory elements of the IRATA syllabus as detailed in IRATA TACS Document and the company training manual. The Instructor will be responsible for course techniques and methods of delivery dependent on the level and candidate group size. The instructor will utilise the company training lesson plan/procedure and Besafety training manual for course delivery at their dynamic discretion and experience suitable to the level of candidates on the course.

3.7When a prospective Instructor employee is unknown to the Rope Access Manager rope access references will be required and checked. In addition new employees may also be given a rope access skills test, conducted by the Rope Access Manager.

3.8The Rope Access Manager will seek to ensure that employed instructors have a suitable attitude and aptitude by interview in addition to their IRATA International Level 3i qualification and use form 004 & 005.

3.9All Instructors will hold a current IRATA Level 3i qualification.

3.10It is company policy to ensure that all Instructor personnel have the necessary levels of natural aptitude, training, assessment and experience to safely carry out their roles and tasks. This will also include as a minimum a ‘self assessment’ certificate of medical fitness and a valid and appropriate HSE approved First Aid and AED certificate.

3.11Instructors will be responsible and should keep their IRATA Log books up to date at all times. In the absence of an IRATA Log Book, operatives must show evidence of training and hours worked. All Instructor staff are required to maintain their IRATA status by undergoing a three-year reassessment by an IRATA independent assessor and renewing annually their instructor status. Personnel with lapsed certification will not be employed by Besafety Ltd. This includes first aid certification. As Per IRATA TACS document instructors must meet the requirements of Instructor status.

3.12Newly qualified Level 3i Instructors will be under the close supervision of the Rope Access Manager. All Level 3i Instructors are given a practical induction to the facility in use by The Rope Access manager and Besafety Ltd’s training lesson plan. In addition all Level 3i Instructors are supplied with a copy of this procedure and a copy is always available at site.

3.13Instructors who have been inactive for a period in excess of 3 months will be required to carry out a short refresher programme before being engaged in training run by the Rope Access Manager using his experience.

3.14Instructors will be chosen based upon their relevant industrial and training experience.

3.15All New Instructor staff will be suitably competent and experienced in their training role. Any specific management training needs will be identified and the necessary actions implemented by the Rope Access Manager.

3.16Records of all employees and subcontractors details and qualifications will be kept on file for records and reference purposes.

3.17For newly qualified instructors, additional precautions need to be taken. These include only gradually introducing them to the training work under supervision of the Rope Access Manager. All candidates should be under close supervision at all times.

IRATA Qualification

3.18IRATA Level 3i, this is an experienced rope access technician who is responsible for understanding and implementing the rope access training procedures, and associated risk assessments, and is able to demonstrate and teach the skills and knowledge required of IRATA Levels 1 and 2 & 3. A Level 3 Instructor is responsible for filling in their own IRATA Log Book & Instructors Log Book.

He/She also:

- Understands the elements and principles of IRATA International’s safe system of work, ICOP and TACS Document

- Is conversant with relevant work techniques and legislation

- Has an extensive knowledge of advanced rope access rigging and rescue techniques

- Holds an appropriate and current first-aid certificate

Certification Validity

3.19Instructor staff have the requirement to maintain their IRATA qualification by undergoing a 3 yearly re-assessment via an independent IRATA assessment. Besafety staff with expired IRATA certification will not be employed for IRATA Rope Access Training duties.

3.20Besafety Instructor staff that have not been active in rope access Training for a period of three months or more, will be required to undergo refresher training with the Rope Access Manager in order to demonstrate that they maintain the skills appropriate to their level. This will normally be a minimum period of one day but could be longer.

Logbooks

3.21All Instructor personnel must be in possession of their own IRATA logbooks. These must be kept up-to-date. The Rope Access manager will sign technician logbooks, if this is not possible, then the logbook will be signed by the company administration representative. Candidates are to have their logbooks present on day one of the training course for the Instructor to check valid and up to date.

Personnel Files

3.22A Personnel file is kept for all employed rope access Instructor staff which will include the following documents:

- Copy of current valid IRATA certificate including First Aid Cert

- Self Cert Medical Form

- Signed copies of induction form 009

- Signed Copies of Document Receipt forms

- CV

Staff Induction

3.23All Besafety Instructor Staff will be given an induction by the Rope Access Manager. It will be recorded on the induction form 004 and signed by the inductee and inductor. It will include but not be limited to:

- Employed Individual responsibilities

- The Employment terms for all staff

- Communication

- Company Structure

- Company Safety

- BE.01 Rope Access Operating Procedures and Associated Forms

- Besafety Training Manual

- IRATA Form 006

- IRATA ICOP

- IRATA TACS

- Training Risk Assessments, rescue plans & Method Statements

Instructors will be inducted by the Rope Access manager on the IRATA Trainer file on the IRATA Website and how to Access it for immediate access to all relevant documents relating to IRATA and its training courses. To include the IRATA ICOP and TACS document, that they can give to candidates in electronic format in their native language as required.

Medical Certification

3.24As a minimum all employee’s and candidates will self-certify, using IRATA form 014R, indicating that they have no contra-indications for this type of work or training.

Insurance and First Aid

3.25Besafety is fully insured for rope access related tasks with the cert being held at head office. Also a full First aid kit is available on site during all training activities. The Instructor in charge is the dedicated First-Aider and will be responsible during the course for the first aid kit.

Disciplinary Procedures

3.26Besafety will procure outside professionals for designated disciplinary processes for all staff if required. The MD will communicate all disciplinary actions or notices in writing under the guidance of an outside legally trained person.

4 Training Methods & IRATA Training Delivery

4.1Besafety IRATA Training Course content will include delivery of all the practical and theoretical elements required by the relevant IRATA syllabus over a minimum of a 4 day period for levels 1, 2 & 3 and cover the requirements of the IRATA TACS Document. Besafety will take all possible and reasonable steps to communicate the course content with candidates from other countries and languages and ensure they understand the techniques and methods. English will be the native tongue and candidates will be made aware when booking. Online language translation may be used for some theory aspects if required for foreign candidates.

4.2The IRATA Training manual appendix document 20 and Besafety Lesson Plan appendix document 019 will be used to deliver the required IRATA syllabus, manoeuvres and techniques by the Instructor in conjunction with the IRATA TACS document and IRATA ICOP Including Annexes.

4.3Rope access candidates are grouped into three technical grades depending on their experience, the Diagram below shows flowchart showing the route to qualification.

IRATA Level 1

This is a rope access Technician who is able to perform a specified range of rope access tasks under the supervision of a Level 3 rope access safety supervisor. He/she is:

- Able to understand and follow the rope access procedures, method statements and associated risk assessments;

- Responsible for pre-use checks of his/her own rope access equipment;

- Able to assist in rigging and other operations, under the guidance of a higher grade;

- Able to undertake a simple rescue in descent and assist in rescue operations.

IRATA Level 2

This is an experienced rope access Technician who is able to perform more complex tasks under the supervision of a Level 3 rope access safety supervisor. He/she is:

- Able to demonstrate the skills and knowledge required of Level 1;

- Capable of more complex rigging, including re-belays, deviations and tensioned lines;

- Able to undertake rescues from a variety of situations;

- Able to assemble and implement hauling systems.

IRATA Level 3

This is an experienced rope access Technician who is responsible for understanding and implementing the rope access procedures, method statements and associated risk assessments, and:

- Is able to demonstrate the skills and knowledge required of Levels 1 and 2;

- Understands the elements and principles of IRATA International’s safe system of work;

- Is conversant with relevant work techniques and legislation;

- Has an extensive knowledge of advanced rope access rigging and rescue techniques;

- Holds an appropriate and current first-aid certificate.

IRATA Level 1 - Rope Access Technician

The Industrial Rope Access Trade Association - IRATA - is the only internationally recognised certification scheme for industrial rope access. The Level 1 certificate is the first step in a three level structure. Candidates should expect a hard week both mentally and physically as they come to grips with the wide range of access techniques required to pass the independent assessment on the final day. As a qualified Level 1, the candidate will always be under the safety supervision of a Level 3. Safety is an overriding concern during training and assessment. It should be noted that this course requires a reasonable degree of physical and mental dexterity as well as a head for heights.

CONTENT

- Rigging, knots and rope work

- Understanding and safe use of equipment

- Rope manoeuvres

- Structural climbing techniques

- Simple rescue

- Background and theory

- General safety and aptitude

WHO WILL BENEFIT? An IRATA qualification is designed to enable qualified industrial tradesmen to access their normal tasks in a safe, efficient and low impact way. Common trades on the ropes include: NDT, inspection, electrical, rigging and painting.

STRUCTURE The course is mainly practical with emphasis placed on learning to perform the techniques safely and efficiently. The course is assessed on the final day by an independent IRATA Assessor. On successful completion the candidate is issued with a logbook, certificate and ID card. Candidates are reassessed three-yearly. The course is of a five-day duration, including assessment.

IRATA Level 2 – Rope Access Technician

The IRATA Level 2 certificate is the second step in the IRATA certification scheme. The Level 2 builds on the Level 1 course material and the candidate's practical experience. More in depth rigging and rescue techniques as well as a higher degree of proficiency on the ropes consolidate the candidate's experience and offer an introduction to the advanced techniques of Level 3. A Level 2 certificate confirms the candidate's experience and competence to operate as a reliable worker.

CONTENT

- Proficiency in all Level 1 techniques

- Enhanced rigging techniques

- Rescue from Ascenders

- Rescues from manoeuvres – aid climb, deviation, rebelay, rope transfer

- Hauling and lowering casualties

- Level 2 theory

- Equipment selection, inspection, care and maintenance

WHO WILL BENEFIT? IRATA Level 1 technicians wishing to progress through the system. Candidates must have a minimum of 1000 logbook hours and one years’ experience, ideally in a variety of locations.

STRUCTURE The course is mainly practical with the emphasis being placed on building the candidate's confidence and competence in the discipline. Independent IRATA assessment is carried out on day 5. Successful candidates receive a new certificate and ID card. Certificate is valid for three years. The course is delivered over a five-day period, including assessment.

IRATA Level 3 – Safety Supervisor

OVERVIEW

The IRATA Level 3 certificate is the top level in the IRATA certification scheme. The Level 3 builds on the candidates experience and prepares him to take on the roles of Team Leader, Safety Supervisor, Rescue-man and Rigger. Thus far IRATA rope access has an impeccable safety record, this is largely due to the quality of Level 3's in the field. This course aims to maintain, and build on, these high standards.

CONTENT

- Current legislation and regulations

- Equipment selection, inspection, care and maintenance

- Operational planning and risk assessment

- Proficiency in Level 1 and 2 techniques

- Advanced rigging techniques

- Advanced rescue technique

- Team Management and responsibilities

WHO WILL BENEFIT? IRATA Level 2 technicians willing and able to take on the responsibility for a rope access team. Candidates must have completed at least a year and 1000 hours as a Level 2 and should have a broad range of experience of different working environments. We would only encourage top quality candidates to apply.

STRUCTURE The majority of the course is spent practising and refining advanced rescue techniques so that the candidate has the ability and confidence to extract any team member from any possible difficulty. There is also a written paper which concentrates on the candidate's theoretical knowledge. This course is delivered over a five-day period, including independent IRATA assessment.

4.4On the final day of an IRATA Training course an Independent IRATA assessor will be booked and carry out an independent assessment of Candidates.

4.5IRATA Assessors will be required to have their own insurance relevant to the activities being undertaken.

4.6On completion of assessment the IRATA assessor will thoroughly debrief all candidates and inform them of their results with the Instructor present.

4.7In the case of a pass at any level the assessor will complete, grade and sign the IRATA assessment form, including any comments. An App enabled ADF is currently being implemented whereby assessors can sign off assessments electronically.

4.8The trainee will be required to sign the assessment form indicating that they agree with the results of the assessment and that they have been trained in all the elements of the syllabus relevant to their level.

4.9The trainer will be required to sign the form indicating that they have delivered all the elements of the IRATA syllabus relevant to the trainee’s level.

4.10In the case of a candidate not achieving a pass the assessor will fully explain the reasons for this and inform the candidate of possible courses of action, e.g. further training etc.

4.11Besafety Ltd reserves the right to remove anyone from a course who proves unsuitable, for whatever reason, to the demands of rope access training. In these cases all or part of course fees may be refunded at the discretion of the Rope Access Manager.

4.12The primary objective behind the planning and management of IRATA rope access training is to create a training environment that maximizes safety and minimizes the risk of error, possible incidents and injury, and provides a total safe system of training, i.e. zero targeting.

Planning for IRATA Rope Access Training must include but not be limited to:

- A documented safe system of training i.e. Training Manual and lesson plans

- A documented specific venue risk assessment

- Site induction requirements

- Training facilities, e.g. classroom and area for candidate resting and first Aid

- Planning for Rescue and emergencies, e.g. fire

- Protection of third parties, e.g. exclusion zones; barriers; warning signs.

Planning should not only include the selection of appropriate training methods, equipment and competent Instructors but should also include the preparation of a specific rescue plan, e.g. rigging for rescue if appropriate or required. Dependent on levels being trained the Instructor will determine when rigging for Rescue is required.

Risk Assessment

4.13Through careful Risk Assessment The Rope Access Manager will identify any hazards and examine how they can be removed, or, if this is not possible, how the risk can be reduced to an acceptable level. This is determined by carrying out a site specific Training venue risk assessment appendix document 006.

4.14A risk assessment is a detailed and systematic examination of the hazards of IRATA Rope Access Training that could cause harm to Candidates, Instructors or Visitors. A risk assessment must be carried out before Rope Access Training takes place at any training venue including any temporary venues Besafety use. All Instructor Staff must sign acceptance sheet prior to start of work that they have read and understood the Risk Assessment. The risk assessment for IRATA training operations conducted by Besafety Ltd is included as Appendix of this procedure, this is regularly monitored and reviewed in reaction to any change of normal operating conditions at the company’s training venue. All training sites will be risk-assessed, using the same format, prior to commencement of training by the rope access manager.

4.15The detail provided in the risk assessment should be in proportion to the risk. A copy of the Specific Risk Assessment document will form part of the Training Procedures. In addition to the Risk Assessment IRATA form 006 will be completed by the Rope Access Manager and present at the training venue prior to any commencement of IRATA Training. The Rope Access manager will be responsible for keeping the IRATA form 006 up-to-date and relevant to any changes. Form 006 will be completed fully as required by IRATA and all boxes must be completed.

4.16After the hazards have been identified, the risk assessment should continue with a careful study of all the hazards identified, to determine the level of risk posed by each. As a first step, wherever possible, hazards should be eliminated. If this is not possible, precautions should be taken to minimize the likelihood of candidates being harmed.

4.17The risk assessment should include detailed consideration of foreseeable emergency scenarios and Rescue planning as to how any rescue would be carried out known as the Rescue Plan.

A five step process is used to produce the site specific task Risk Assessment:

- Identify the hazards

- Assess the level of risk

- Put control measures in place to eliminate or reduce the risks to acceptable levels

- Record the findings of your assessment and list the control measures adopted

- Review The final stage of the plan is to continually Review the effectiveness of your control measures, and to adjust and revise those measures where necessary in order to maintain the level of risk within acceptable boundaries

4.18The following documents must be present at the Training venue are listed below:

- Besafety Training procedures and Training Manual

- IRATA ICOP and TACS document

- Equipment user instructions

- Copies of IRATA certification for all Instructors

- Copies of Level 3 first aid certificates

- Copy of company insurance

- Risk Assessment & Rescue Plan

- Record of Rope Hours (IRATA Form 055)

- Accident & Incident Report Form

4.19Once Candidates or visitors arrive at the training venue, under supervision of the Instructor they will formally sign in on site in visitors register and Instructor will provide an Induction that they must sign to accept receipt form 009.

4.20The Instructor, shall, before each Training course begins/starts, perform an Induction “toolbox talk” with all the candidates. This will include discussing and reviewing the Welfare Facilities, First Aid, Structures and Anchor system’s Loadings and general Work At Height site Safety Rules, Site Risk assessment, Rope Protection methods required and the Rescue Plan including rig for rescue requirements if applicable. All candidates must sign to indicate that they have received and understood the pre-training briefing on the relevant Induction Toolbox Talk form 009.

4.21Prior to any commencement of training Pre-use checks will be conducted on all personal equipment including pre-use inspection checks of Harness and the Rope Access system. The Instructor will check the condition of all his and his candidate’s personnel equipment, anchor points, ropes, rigging including all training structures and complete form 008.

4.22From the outset of the training the principle of “buddy checking” and inter-team supervision will be adopted and encouraged by the Instructor, including:

- After the trainee or instructor has donned their harness and assembled their equipment

- After the trainee or instructor has attached to the ropes

- Prior to the trainee or instructor committing to the system

- At all times when the trainee or instructor is engaged in rope access manoeuvres

- The limitations and dangers through poor handling and misuse of devices are highlighted to trainees during the training course and using the foreseeable misuse Risk Assessment document.

4.23Also From the outset trainees will be encouraged to habitually conduct pre-use checks on their equipment.

4.24All equipment in the Training venue should be checked before use to ensure it is in good condition and functions correctly. Before candidates approach the point of descent or ascent, or commencing to descend or ascend, checks should be made to ensure:

- Harnesses and helmets are correctly fastened and adjusted;

- Lanyards and connectors are correctly fastened;

- Anchors are appropriate and secure;

- Working lines and safety lines are the correct length for the task, are anchored correctly and are free from damage;

- Stopper knots are tied at the lower end of both the working line and the safety line at an appropriate position, with an allowance for stretch;

- Other items are secured so they cannot fall.

NOTE: The checks above are also best carried out by a co-candidate. This is known as a buddy check.

Additional checks should be made by the Instructor to ensure:

4.25Anchor lines are rigged so as to avoid being damaged during the training task, and anchor line devices are attached to the anchor lines correctly.

4.26The Instructor will continually monitor the condition of all equipment and anchor points; in addition they will continually monitor the effectiveness of the control measures in place to maintain the safe Training conditions of the training venue.

4.27In any potential pendulum situations, i.e. manoeuvres involving horizontal displacement of ANY distance, secondary back-up devices are deployed in both directions i.e. Re-Anchors, Rope to Rope Transfers, Deviations.

4.28During training courses, access to the training facilities will be restricted to personnel directly involved in training operations. As per Risk assessment Protection measures include signs and barriers at all possible entrances to the training areas. At all times a Climbing helmet must be worn at ground level within the demarcated training area by both instructor and candidates. All tools or potential for dropped objects must be controlled by use of lanyards or cow’s tail connected to prevent them falling.

4.29Where unauthorised personnel could gain access to anchor points then these shall be appropriately protected against interference, including signs and barriers and possibly specialist rigging techniques and equipment.

4.30The training facilities are controlled environments where constant voice audio-visual communications can easily be maintained between instructor and trainees. Any special measures required to maintain good communications will be adopted as appropriate.

4.31All main anchor points consist of primary attachment point and a completely separate secondary back-up point. All ropes are independently anchored.

4.32All training is carried out on a two-rope system. In the event of failure of the primary (working) rope or any part of the system it is attached to, then the secondary (back-up) rope system would engage providing security to the trainee or instructor.

4.33Candidates and instructors attach to the two-rope system in such a way that the principle of 100% back-up is maintained throughout the whole training system at all times:

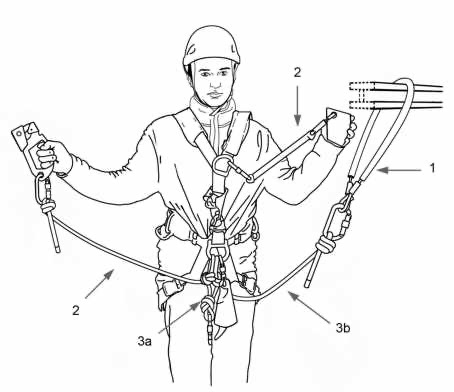

- Cowstails are individually and independently knotted and attached to the central harness D-ring from one continuous EN 892 dynamic rope

- A compliant EN355 energy absorbing lanyard with Petzl ASAP mobile fall arrester used as the back up device will be attached to the sternal attachment point on the harness, this will be attached to the back-up rope. A second back up Device ‘DUCK’ will be utilised in ALL Rope transfers on the back up rope being ascended

- Ascending or descending equipment will be attached to the other (working) rope

- For aid-climbing the Candidate will at all times be attached to a minimum of two cowstails, these will in turn be attached to separately anchored slings, or eyebolts thus maintaining the principle of independent back-up at all times

4.34All main anchor points within the facilities are suitable for intended use; they are of two main types, either:

- Minimum 7mm Steel Wire Slings or Textile slings - EN 795B anchored to structural steelwork, or

- EyeBolts – EN 795 A1, used in pairs

4.35Either anchor system will achieve a minimum system strength of 15kN as recommended by IRATA ICOP and the engineering calculations for the Besafety Training venue.

4.36Each individual anchor system consists of a minimum 2 temporary EN795 anchor devices attached to the structure, 2 EN362 karabiners and 2 individually EN1891 type A knotted ropes.

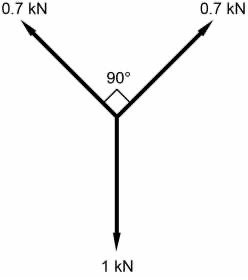

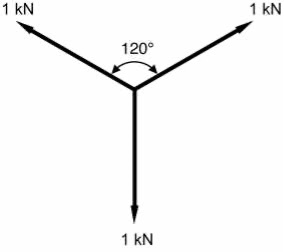

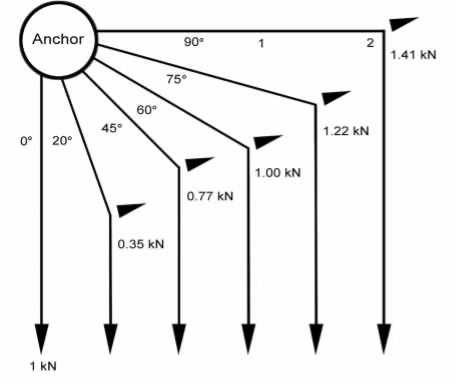

4.37Rigging angles for “Y” anchors, slinging of loads or cross-hauling will not exceed 90°.

4.38Deviations used to redirect ropes should not exceed 20° from the vertical, or the deviation should not be more than 2m lateral displacement from the main anchor.

4.39When training with horizontal tensioned lines candidates are advised that the maximum angle for these is 160° and at that angle the tension at each anchor point is 3 x the load. In these situations trainees are advised of suitable back-up methods and load limiting techniques.

4.40Instructors are responsible for checking that anchor lines are correctly rigged.

4.41Anchor lines should be rigged to avoid any surface that could damage the ropes.

4.42During IRATA Rope access Training Anchor points must be unquestionably reliable. Rope access anchors must have a minimum breaking strength of 15kN. Anchor points consist of a primary attachment point and a secondary back-up anchorage. All ropes are independently anchored, but both anchors may be connected to each other in such a way that there is share loading.

4.43The working line and the safety line are known collectively as anchor lines. Each anchor line should be attached to its own anchor point. The working line and the safety line are normally connected to each other for added security, as well as allowing the anchor lines to be positioned between the anchors. Load sharing between anchors reduces the load on each one. This minimizes the likelihood of failure of either anchor but, in the unlikely event of a failure of one of them, there would only be a minimal impact force on the second anchor.

4.44Instructors and candidates MUST always be attached to at least a minimum of TWO independent systems, such that failure of any one anchorage, rope or item of equipment will not cause the operator to fall, i.e. 100 per cent redundancy.

4.45A primary device of either a Descender or Ascender will be connected to the Working Rope with a suitable back up device connected to the safety rope. When working in suspension on the ropes the harness set-up for technicians will be such that it provides independent attachments to the working rope and back-up rope.

4.46The principle of double protection also applies to the attachment of rope access technicians via their anchor line devices to the working line and safety line and to any anchors by their anchor lanyards. For example, descending devices and back-up devices should be fixed to the rope access technician's harness with separate connectors, in accordance with the information supplied by the manufacturer. (It is not necessary to wear two harnesses).

4.47Personal rope access equipment will only be used for its intended purpose in accordance with the manufacturer's instructions and must not be used for lifting loads.

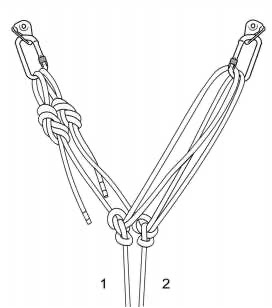

4.48At all times candidates must connect both working and back-up rope to both independent anchor points with a ‘Y’ hang system to create share loading as per IRATA ICOP and supervised by the Instructor as per diagram below.

Normal Anchor Arrangement

Maximum Rigging Angle

4.49Rigging angles should if possible, not exceed 90 degrees AND definitely not exceed 120 degrees as per drawings above.

4.50When working in suspension the harness set-up must provide independent attachment to the working rope and back-up rope.

4.51Instructors should Ensure there is a minimum amount of rope on the ground, Ropes must be knotted at the lower ends to provide rope length security.

4.52The following are used at Besafety training venue as suitable Anchors:

- Structural Anchors including training rig and towers minimum strength 15kn

- Designed, Tested permanently installed Class A1 Anchorage devices (Eyebolts) 15kn

4.53Anchors should be positioned in such a way that candidates can maintain their work position without difficulty and so that connection can be made to or from the rope access system in an area where there is no risk of a fall from a height.

4.54Wherever feasible, the two independent anchors – one for the working line and one for the safety line, and each with a static strength of 15 kN or more – should be linked together for added security. This link can be achieved, for example, by the use of a double figure-of-eight knot on the bight (also known as a bunny knot) or a combination of a figure-of-eight knot on the bight and an alpine butterfly knot.

4.55Anchor lines should be configured so that a candidate or instructor cannot inadvertently descend off the end of them. Where the anchor line is free hanging, this may be achieved by the use of a simple stopper knot.

4.56If exit from the bottom of the anchor lines is planned, a check should be made to ensure that the anchor lines reach the bottom, or if being carried in a bag, that they are long enough. It may require the instructor to check this.

4.57Slack in the safety line should always be avoided to minimize the length of any potential fall in a dynamic rope failure the Instructor will monitor this.

4.58To minimize the length of any potential fall, connections to safety lines should, wherever possible, always be positioned above the rope access technician’s harness attachment point, with the least amount of slack achievable in the device lanyard. This may not be possible with back-up devices intended to follow the user. However, in all cases, when the rope access candidate is not in motion, the back-up device should be positioned as high as possible.

4.59Attaching to or detaching from anchor lines at mid-height may present problems. Anchor lines should be checked carefully to ensure there is no build-up of slack between the anchors and attachment point that could become snagged and release suddenly. Where the whole length of the anchor lines can be seen, these checks can be visual.

4.60Where there are long anchor lines above a short drop, previously unloaded anchor lines may stretch suddenly when loaded, allowing a candidate to drop a distance proportional to the length of anchor line above, possibly causing him/her to hit an obstruction or the ground. In addition, if the working line were to fail at this point, the stretch generated in the safety line could result in insufficient protection, irrespective of the type of back-up device used. A solution is for the instructor or candidate to re-anchor both anchor lines and thus remove the problems of excessive elongation.

4.61When anchor lines are tensioned, for example, as they are in horizontal anchor line systems, the increased loads in the system, e.g. at the anchor, anchor line terminations and at other components, should be considered.

4.62Where anchors are over 1.5 metres apart anchor devices will be doubled to prevent failure of the anchor system should one connector fail.

4.63When working with tensioned lines technicians are advised that the maximum angle for these is 160° and these techniques should only be used after careful consideration, including specific risk assessment.

4.64When engaged in aid-climbing the set-up should continue to ensure a minimum of two independent attachments by use of two EN892 dynamic rope lanyards to two independent anchors.

4.65When work seats are used the candidate must always be anchored independently of these items by maintaining their full rope access system at all times. Work-seats are to be used for comfort only and must not be used as the technician’s fall protection.

4.66Candidates should not ascend or descend any anchor lines without confirmation from the Instructor that it is safe to do so, following pre-descent/pre-ascent checks.

4.67Candidates should normally descend vertically with the minimum amount of swing (pendulum) to minimize any risk of abrasion to the anchor line or putting unnecessary stress on it or the anchors.

Deviation Anchors

4.68Where anchor lines need to be redirected, the angle and loading at the deviation anchor and supporting equipment used should be taken into account before use, together with what might happen in the case of failure. Failure could cause an out-of-control swing fall (a pendulum), which could result in injury to personnel or damage to equipment or property. A large deviation angle could increase the difficulty for the candidate in maneuvering past the deviation anchor, so a re-anchor might be more appropriate. Deviation anchors are also used to avoid hazards, e.g. sharp edges. They should be robust enough not to fail at any potential load to which they could be subjected.

Besafety utilise two types of Deviation Anchorage:

- Positional, to provide position on the workface. In these cases a single deviation anchor may be appropriate, i.e. where the consequence of anchor failure would be a small swing which has no potential for injury or rigging damage. Single deviations will not exceed 20° from the vertical.

- Double-anchor deviations may be used to deviate the ropes by a greater angle and distance than a single anchor deviation, and / or may allow the ropes and user to be protected against more serious hazards such as a sharp edge or a large swing into a structure. Such a deviation utilizes a double anchor system, with suitably rated main anchors and connection components, to provide protection against failure of any one anchor item. Where a large angle is created, Instructors and candidates should consider whether a re-anchor may be more appropriate. The diagram demonstrates loadings of deviations.

If a Candidate is unsure about any of the required deviation techniques, they should communicate with the Instructor.

4.69Candidates must ensure that they are protected when within the rope access area i.e. protecting from falls, trips hazards whilst rigging and approaching the rope access drop area including all fall risks as identified in site risk assessment. Suitable precautions will be taken to ensure that access to and egress from the anchorage points shall not be compromised.

4.70No Candidate should be allowed to enter the working edge hazard zone for any purpose, unless they are wearing a harness and helmet and are attached to an anchored safety line.

4.71As identified in the site specific Risk assessment where the training task creates a hazardous and dangerous area by conducting the training task, i.e. removal of guardrails this area should be clearly identified as a rope access danger zone and all necessary controls should be in place to protect candidates and staff and third parties. To ensure that third parties cannot accidentally endanger themselves it may be necessary to appoint a sentry to ensure that exclusion zones are maintained.

4.72Candidates must never approach an unprotected edge without being attached to a safety line when within 2m of the edge.